Surface Protection Against Damage During Handling and transportation

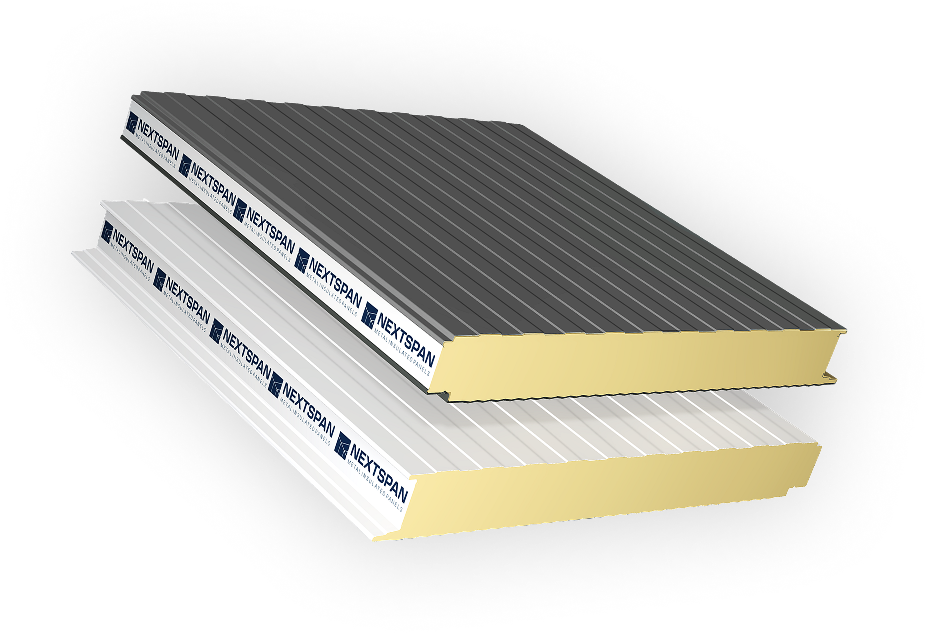

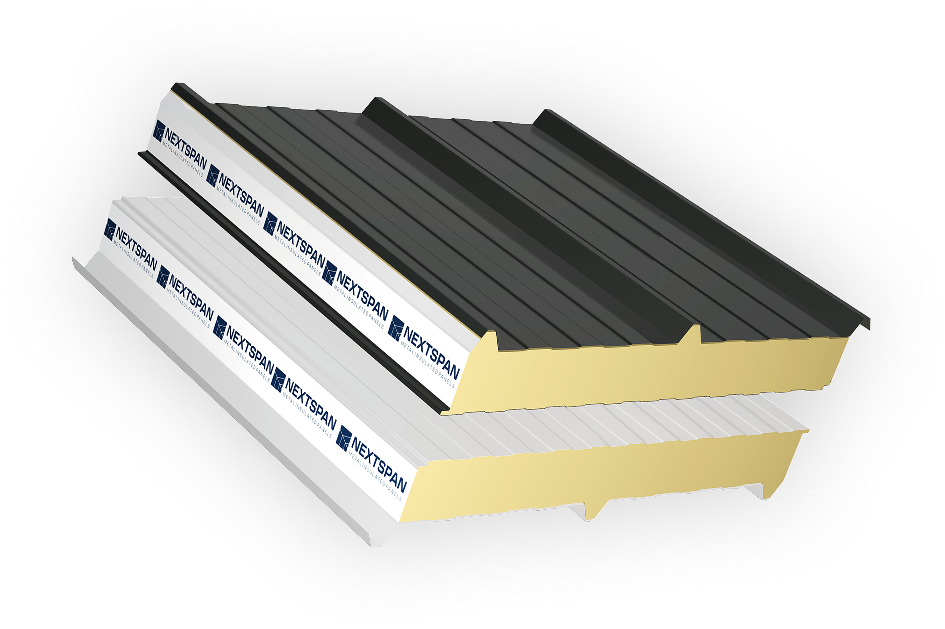

It has strength in the framework and is composed of the metallic facings and the rigid PIR core. The steel facings are galvanized, which gives them mechanical rigidity, impact resistance, and stability in dimensions. The bonded PIR core spreads the loads evenly on the panel. This type of construction of a sandwich permits the panel to resist the bending, winds, as well as service load, and at the same time is light in weight.

The steel facers are bonded to the insulation core with high-performance lamination adhesives, which are applied under controlled conditions of manufacturing to guarantee a strong and stable bond between the steel and insulation core. These adhesives are chosen on the basis of their shear strength, heat stability, moisture, and age resistance. The combination of the materials creates a structurally sound panel that would not fail even at different temperatures and under long-term application.

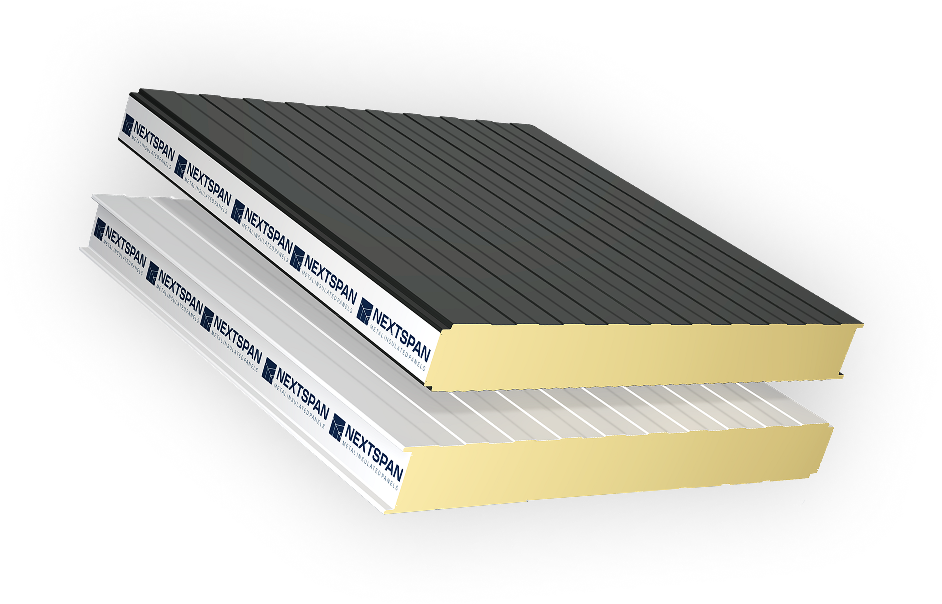

The NEXTSPAN panels are characterized by thermo-performance, which is mainly determined by the PIR (Polyisocyanurate) foam-core; the insulation material is a closed-cell foam product that has extremely low thermal conductivity. The closed-cell molecular structure entraps the gases of the blowing agents in the foam and dramatically decreases heat transfer by conduction and convection. Innovative, ozone-free blowing agents also enhance the efficiency of insulation and, at the same time, prevent a compromise to the thermal stability in the long run.

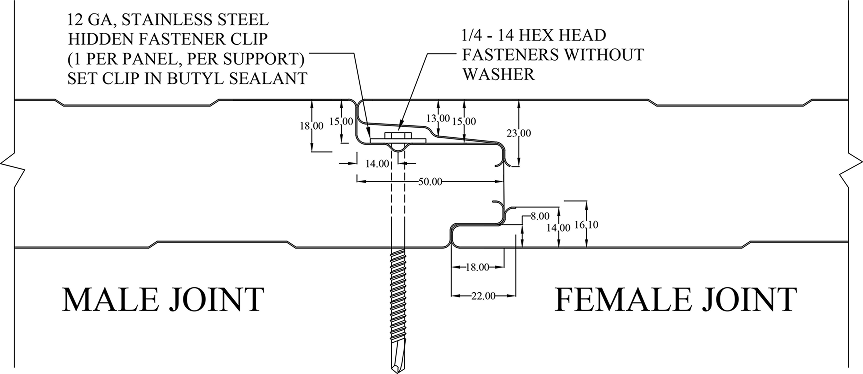

The efficiency of the energy saving is achieved through the configurations of parts of the panel through precise engineering of the panel joints with secret-fix, which minimizes thermal bridging in the connection point. Tight air and vapor influx, particularly heat loss and leakage of air, are reduced by insulation around the entire panel surface.

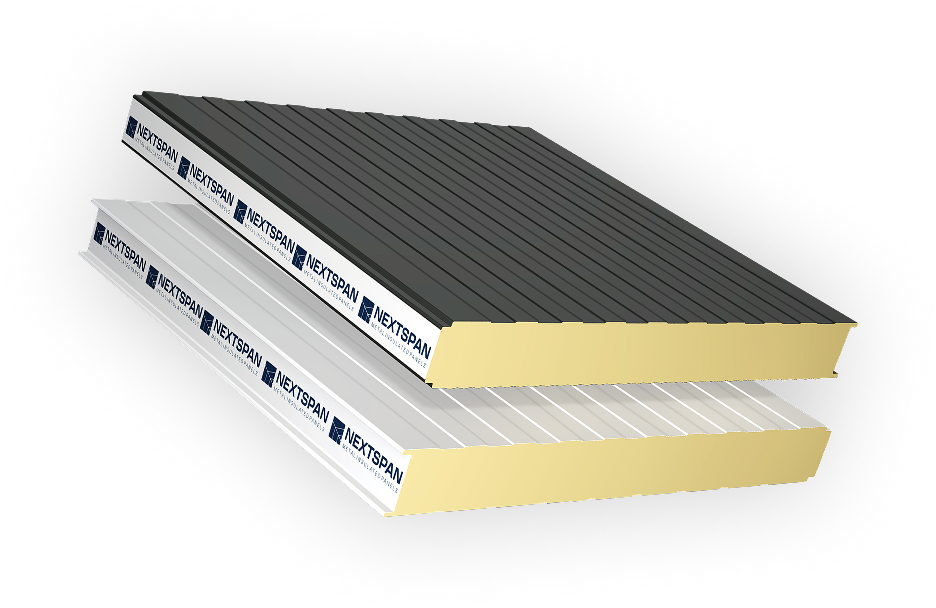

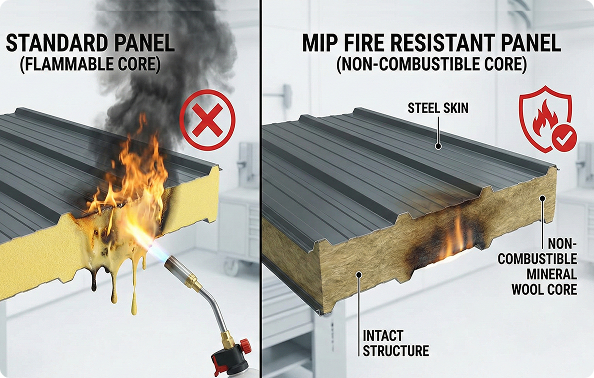

NEXTSPAN panels are primarily affected by the fire-retardant chemistry of the PIR foam core in determining fire performance. PIR foam has the attribute of creating a self-char layer when subjected to heat, and this impedes fire propagation as well as heat dissipation. This chemical action enhances the resistance to fire over the conventional foams and restricts the generation of smoke, which is toxic.

The galvanized steel facings serve as fireproof protective barriers, which protect the core against direct flames, as well as decrease the oxygen supply. The panel joints are formed to reduce the penetration of flames and smoke, whereas adhesives and their coating are chosen to comply with the fire performance standards. Put together, these materials can facilitate adherence to fire tests and increase the safety of the building in general.

NEXTSPAN PROJECTS

NEXTSPAN PROJECTS